Aluma-Tough Metal Tags Last Longer than Stainless Steel!

High-Resolution | Corrosion-Resistance | Fastening Reliability | Ease of Manufacturing | Cost-Effectiveness

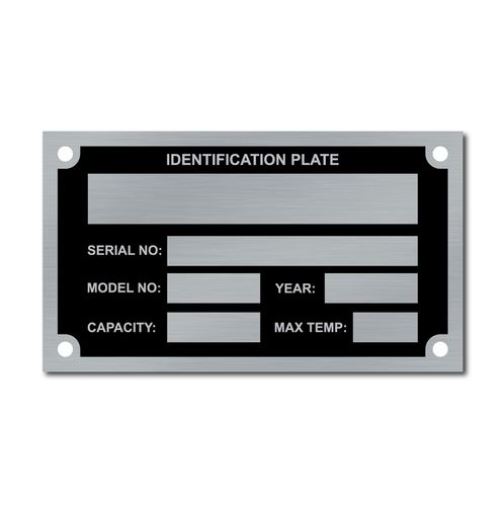

The importance and multifaceted uses of ultra-durable, Aluma-Tough name plates, tags, and signs are clear to the industries that rely on them for presenting information, instruction, and so on.

However, some debate remains about whether using anodized aluminum for such applications is the best approach, and if the much older method of using stainless steel is still a viable option.

We’re here to set the record straight.

High Resolution Printing vs. Etching

Stainless steel metal tags are made by etching and filling the metal. Details like serial numbers, barcodes, etc. are etched or engraved into the surface of the metal and filled with ink.

While this is a satisfactory method for some signage, it cannot provide the level of detail, anti-counterfeit measures, or graphic tolerance of exposing high resolution digital images to anodized aluminum.

As time passes and stainless steel is exposed to the elements, the ink can fade and bleed, losing legibility. In the case of barcodes or other scannable designs, this reduction in resolution over time renders them all but useless.

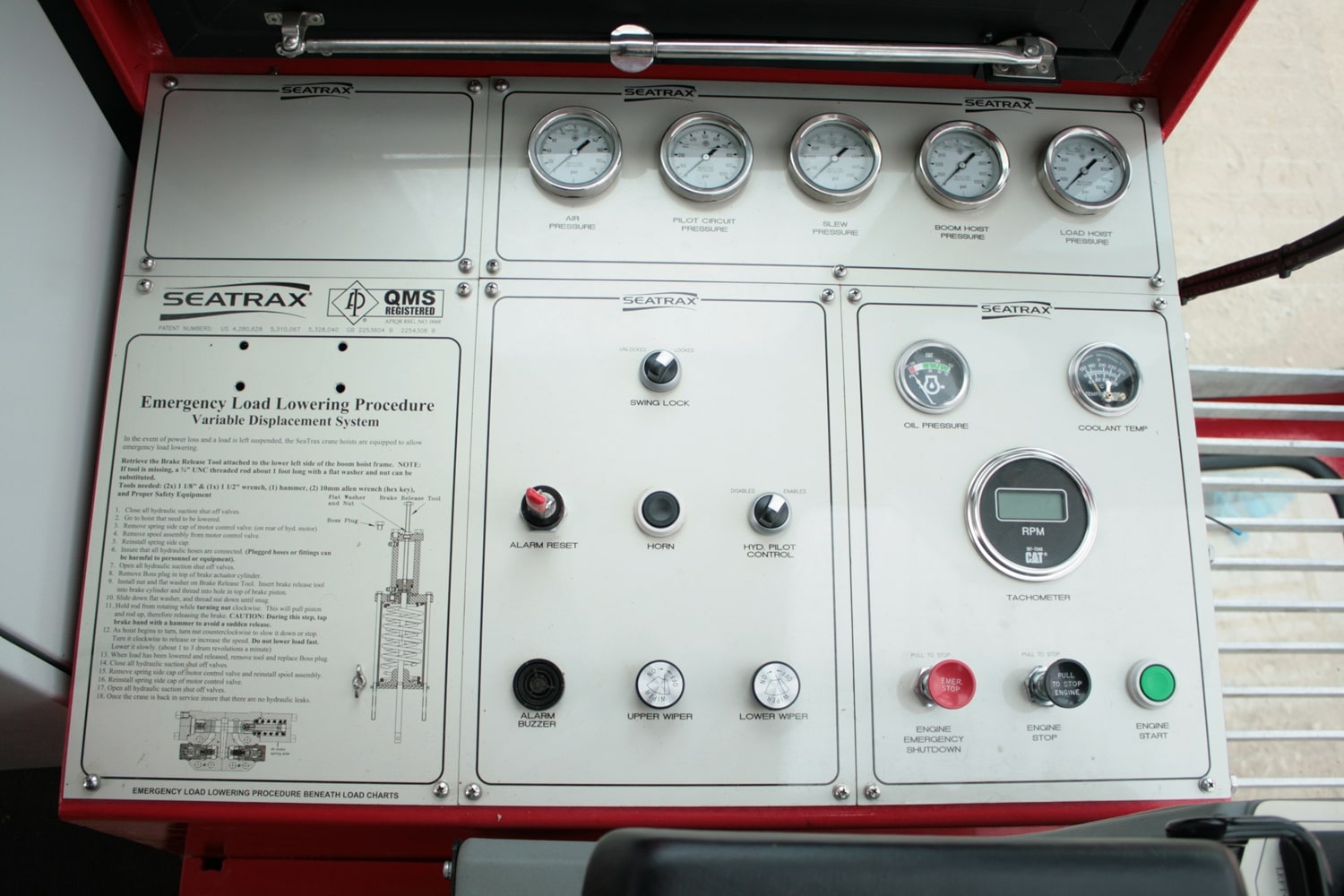

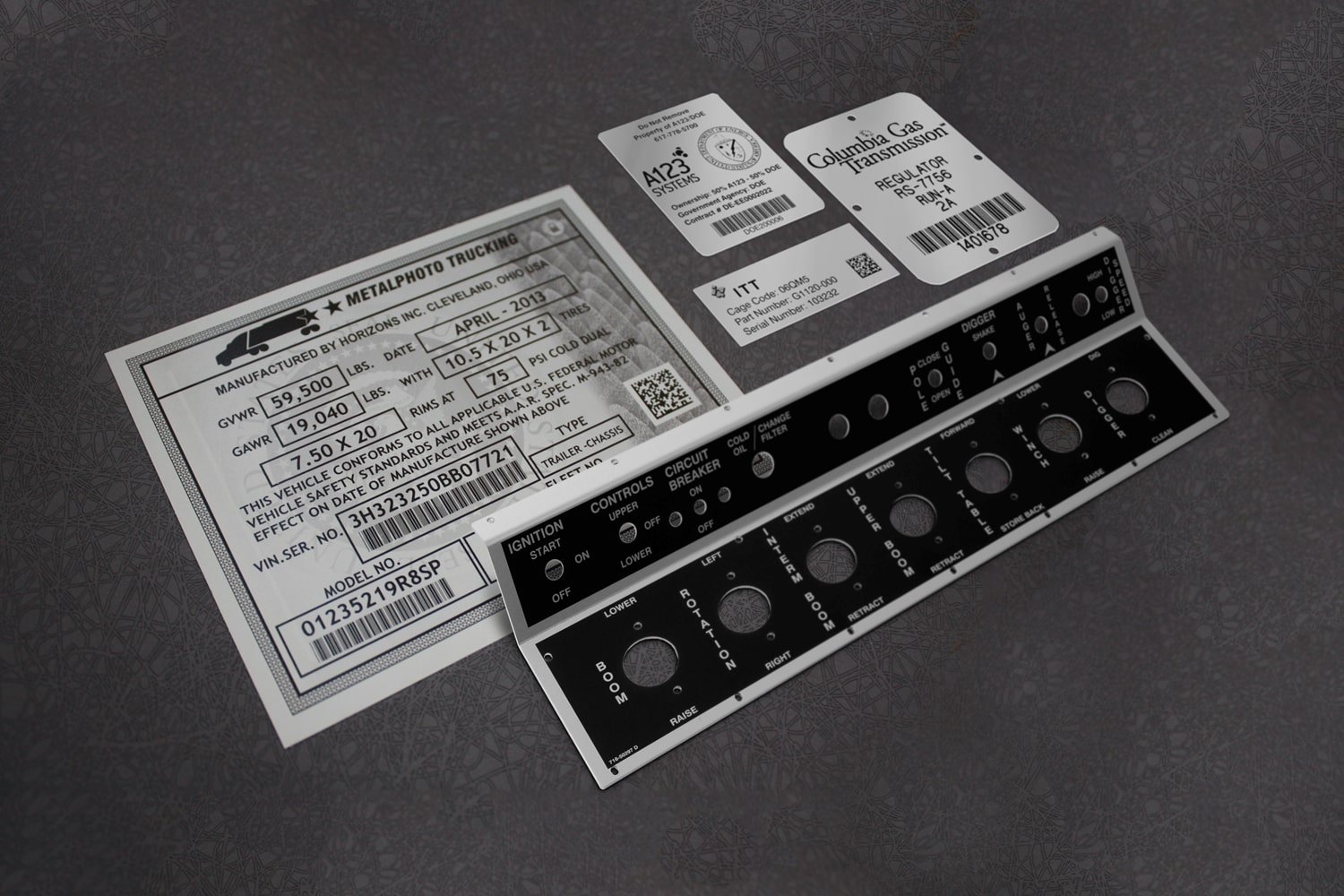

The high resolution and scalable images used in Aluma-Tough products also allows for detailed designs such as wiring diagrams, or extremely small labels on firearms, control panels, and vehicle identification plates.

Corrosion-Resistance

While stainless steel is corrosion resistant in some instances, it simply cannot keep up with the harsh demands of many plate and tag applications. In numerous tests and real-world scenarios, stainless steel shows far more deterioration from exposure to saltwater, chemicals, extreme temperatures, and other environmental conditions.

The sealing process used with Aluma-Tough anodized aluminum creates a sapphire-hard layer that can withstand the harshest conditions for upwards of 25 years, even after prolonged exposure. This, combined with general durability of the aluminum base layer, means that Aluma-Tough outlasts stainless steel in every potentially corrosive environment.

Attachment & Fastening

Some believe that attaching an aluminum plate to a steel substrate surface can cause corrosion.

Extensive testing within the marine industry, and others, has confirmed that with a proper insulating layer of adhesive it does NOT cause unexpected corrosion.

Experiments with a variety of materials, fastener types, sealing agents, and more have proven that Aluma-Tough tags pose no significant risk of corrosion when properly attached to steel.

Ease of Manufacturing

While the printing, exposing, developing, and sealing process may sound complex, it’s actually far less difficult than individual etching and engraving.

The variables happen at the design phase, with high resolution digital images that can be easily altered and adjusted within design software – the rest of the process remains the same.

Customization with stainless steel, or even producing plates with variable data (like serial numbers) can lead to prohibitive costs and time spent because the actual manufacturing is so much more labor intensive.