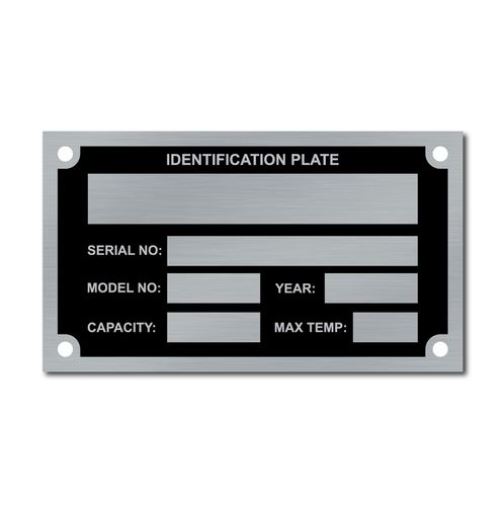

The Process of Manufacturing Aluma-Tough Tags

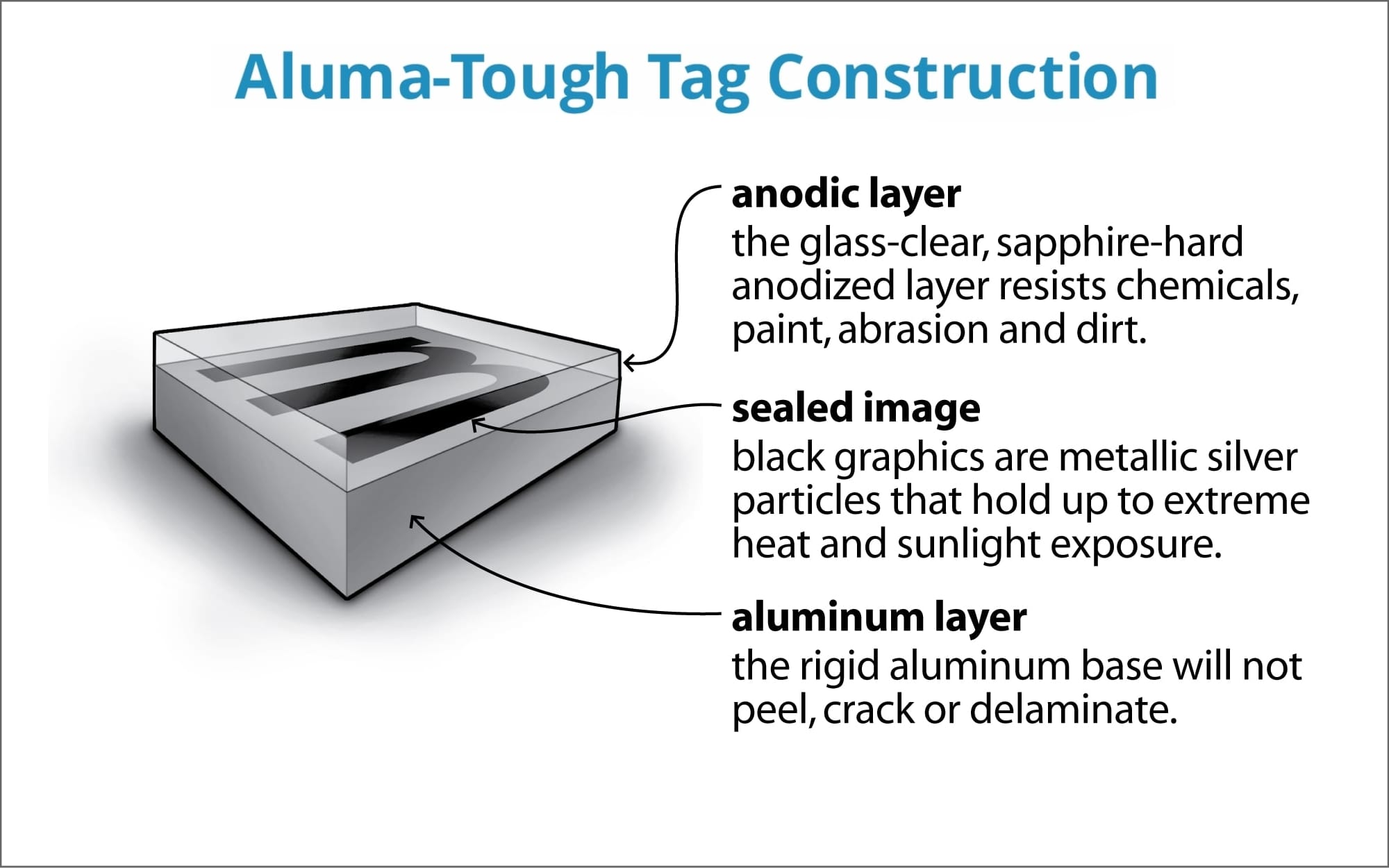

How our sealed, anodized aluminum ID tags are made is what makes them superior in every way!

The true value of Aluma-Tough tags and name plates begins with the manufacturing process.

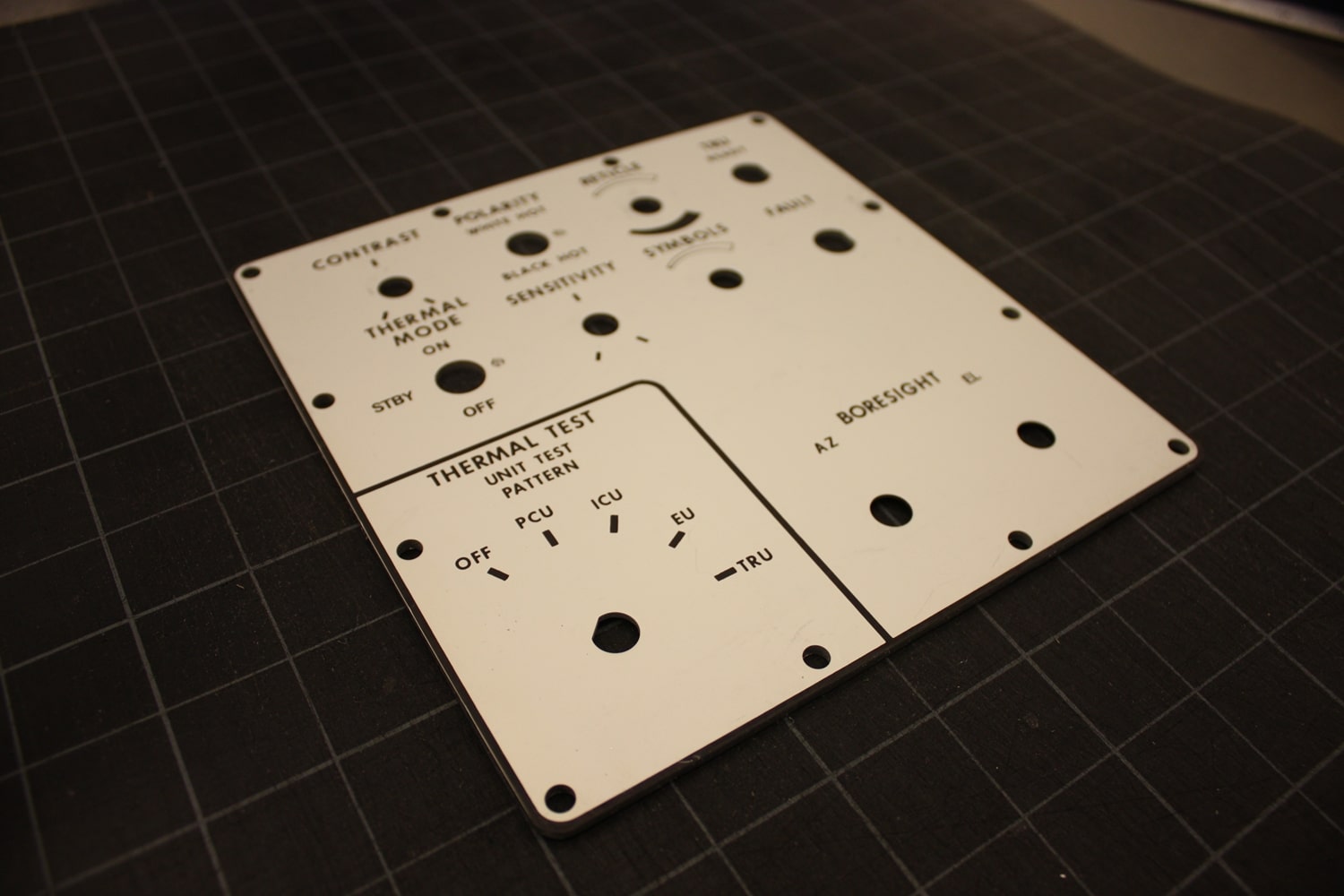

This sophisticated method of printing and sealing images to high quality aluminum ensures clarity and durability for a wide range of applications.

Design

Before an image can be sealed onto an anodized aluminum plate, it needs to be designed.

The design phase may look different for each and every Aluma-Tough tag, plate or sign, depending on its intended use, but it’s always the first step.

Whether it’s gathering images or photographs, writing copy, or organizing all of the technical specs to be included, it’s important to take the time to get your design in order before the rest of the process.

The graphic design team at Nap Tags can help! Contact us to learn more.

Printing

Using a special film, the design is printed to a high contrast, silver-halide film negative that is specially formulated for exposure on anodized, photosensitive aluminum.

The image is then exposed onto a photosensitive aluminum plate using extreme UV light which results in a chemical transfer of the high-resolution, silver halide image into the pores of the anodic layer of the aluminum surface.

Once the image has been exposed onto the aluminum plate, a chemical process is used to permanently affix the image, bring out desired colors and details, and ensure the high resolution of the exposed image.