Sealed Anodized Aluminum vs. Stainless Steel

What’s more durable than Stainless Steel ID tags? Aluma-Tough sealed, anodized aluminum!

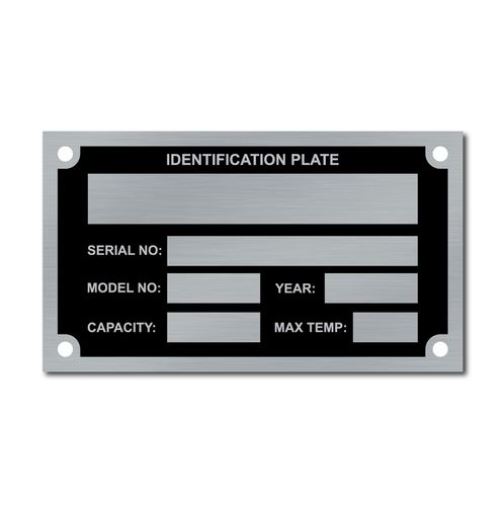

The need for heavy-duty, tough-as-nails metal signs, name plates, and tags is universally accepted among a vast range of industries, but some debate remains about the best materials and processes to use for the best results.

The debate typically comes down to anodized aluminum vs. stainless steel, but it’s clear from performance studies and individual customer experience that Aluma-Tough technology wins out time and time again.

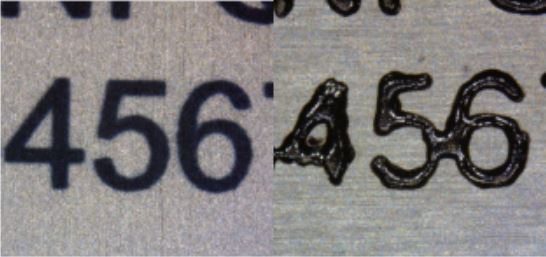

Close-up Aluma-Tough vs. Stainless Steel

Aluma-Tough Costs Less

Even before performance issues, the first point of concern about metal ID tags is typically cost. Businesses and governments need to keep their bottom line in mind, and many people mistakenly believe that stainless steel signage comes at a lower price point. Simply put, it doesn’t!

The cost of raw materials can fluctuate, of course, depending on a number of global factors, but the real price difference between aluminum and steel tags and signs comes from the manufacturing process. Aluma-Tough uses a process of photographic exposure and sealing to imprint graphics onto anodized aluminum, largely handled by machines, utilizing high resolution digital images, and can be created by a single operator.

Alternatively, stainless steel signs are made by etching into the metal and filling the images with special ink – a process that requires both more people and more steps than Aluma-Tough imaging.

The use of digital imaging also means that variable details – like serial numbers, VINs, etc. – are easily interchangeable without additional punching or engraving. This ease of variation also makes it easier to create small quantities of customized name plates, tags, and signs without a drastic increase in labor.

All of this combines to make anodized aluminum the best choice from a cost perspective, and as you’ll see in the sections below, that’s just the beginning.

Aluma-Tough vs. Stainless Steel with Saltwater Corrosion

Aluma-Tough vs. Stainless Steel After 24-hours at 700°F

Clarity and Legibility

Many of the most common uses for metal tags and plates require detailed information, often rendered at a very small size. Whether it’s a control panel on a helicopter, a wiring diagram for a complex machine, or a scannable barcode for labeling chemical storage, the information presented is critical – and needs to be clearly legible.

While the naked eye might not immediately notice the difference, the resolution of an image exposed onto an aluminum substrate is far higher than one etched into stainless steel. The reason for this is straightforward – an etched image is physically carved into the steel surface, and even the highest quality etching isn’t going to create perfect edges. Digital imaging, however, can be scaled to size, and the exposure process transfers a pixel perfect image on the photosensitive aluminum.

From multiple perspectives, including the costs, durability, and clarity discussed here, Aluma-Tough signs, plates, tags, and other products are a better option than stainless steel at nearly every turn.

Aluma-Tough lasts longer, is easier to read, and ultimately cost less. The debate may persist, but the winner is clear!

More Case Studies on Aluma-Tough Tags

Medical Device Tags Withstand Repeated Sterilization

Medical Device Tags Withstand Repeated SterilizationHealthcare providers label and identify property and processes in order to keep track of inventory, communicate hospital procedures and manage recalls. Medical devices or equipment that must undergo sterilization or...

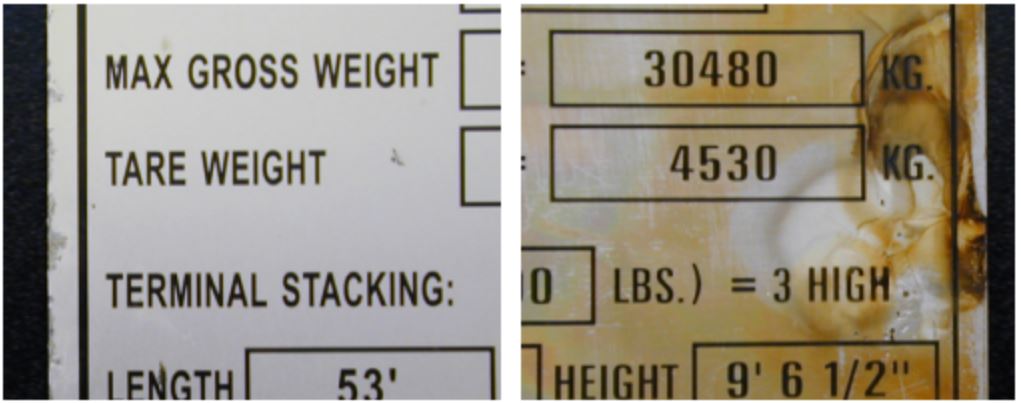

Aluma-Tough Tags are an Asset to the Transportation Industry

Aluma-Tough Tags are an Asset to the Transportation IndustryThe transportation industry encompasses a massive range of vehicles, aircraft, ships and systems, all of which have specific needs for durable, long-lasting ID tags. Aluma-Tough anodized aluminum tags are...

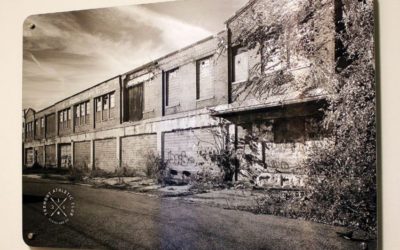

Beautiful Photography Prints on Aluma-Tough Metal

Beautiful Photography Prints on Aluma-Tough MetalThe uses for Aluma-Tough, sealed anodized aluminum signs are numerous, and also include amazing, high-resolution photographs! Although Aluma-Tough is commonly used for industrial applications, such as control panels,...

Aluma-Tough Test for Durability

Aluma-Tough Metal Tags Test of Durability as IUID LabelsPhoto-exposed, sealed anodized aluminum plates, like our Aluma-Tough tags, are commonly used by the United States Department of Defense for IUID barcode plaques. The Item Unique Identification (IUID) program...